Can NAIT help make the trucking industry more environmentally friendly?

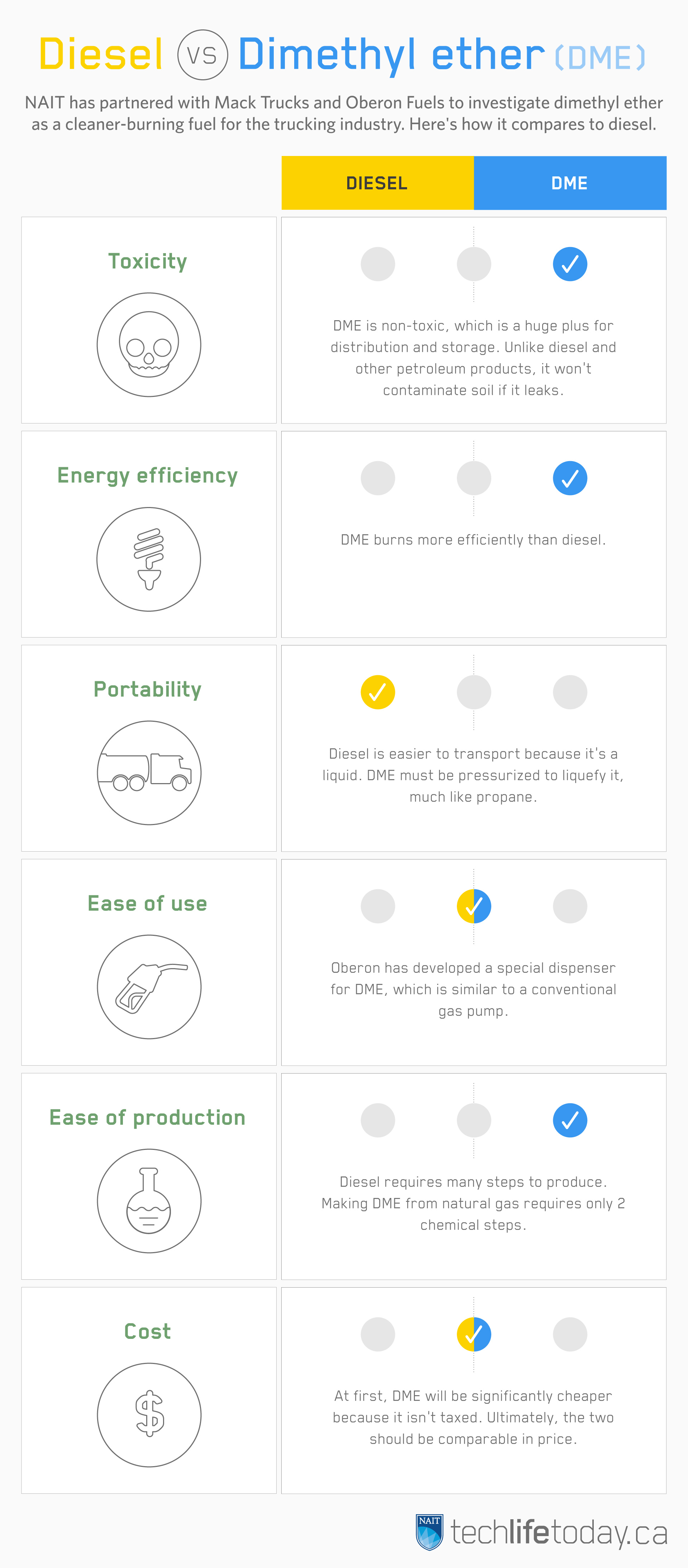

A new applied research partnership at NAIT could dramatically reduce greenhouse gas emissions by replacing diesel fuel with a clean-burning, non-toxic alternative that can be easily produced in Alberta.

“It’s really interesting and exciting for us to explore because the pieces are all there, but they were not connected before,” says Dr. Paolo Mussone, NAIT’s applied bio/nanotechnology research chair (pictured above right with Dr. Glenn Feltham, NAIT president and CEO). The initial phase of the project, funded by Alberta Economic Development and Trade, brings NAIT researchers together with Volvo – which owns Mack Trucks – and California-based Oberon Fuels, the only North-American producer of dimethyl ether or DME.

DME is produced from methanol, which can be made from natural gas or from wood chips left over from the pulp and paper industry. Alberta has plenty of both. Mussone and his team at NAIT will be testing ways to remove water from DME so it can fuel Volvo’s diesel engines without corroding them or reducing their performance.

Volvo was looking for an extreme climate in which to test the technology, and Oberon was looking for a location with plenty of feedstock to make DME. NAIT will provide the expertise in chemistry to de-water the fuel, and in skilled trades to retrofit the engines.

"We are the first to support an emerging fuel technology platform as a continuum, as a value chain."

“NAIT focuses on market-driven, applied research rather than curiosity-driven research,” says Mussone, “and by virtue of this we are the first to support an emerging fuel technology platform as a continuum, as a value chain, with all the pieces lined up.”

The first year-long phase of the project will focus on the chemistry required to de-water the fuel and developing prototypes to retrofit the engine. The second phase of the project, for which funding is being sought, will road test the prototypes on Mack Trucks travelling Highway 2 between Edmonton and Calgary and evaluate their performance.

The project has potential to benefit both industry and the environment, says Mussone. “DME burns clean, so you’re not generating any of the noxious particulate that diesel combustion is known for, and that’s very important to the truck companies.” It eliminates the need for expensive and heavy filtering devices on trucks, and offers an immediate environmental benefit.

DME is also more environmentally friendly to produce. Oberon’s calculations show DME made from methanol recovered from a pulp and paper mill would create 90% less greenhouse gases than conventional diesel, says Mussone. “It’s a really compelling story.”